liupeng@fihonor.com

julie@fihonor.com

+86-13475839195

+86-13070805560

Apr 10, 2020

In recent years, with the rapid development of the automobile industry, the driving speed of automobiles continues to increase, and the driving safety and operability of tires need to be focused on in the tire design process. The wet skid resistance, as an indicator to measure the safety of tire travel, is an important performance of tire tread rubber. A large part of the improvement of wet skid resistance is the design of tire formulations, including the selection of raw rubber and fillers. Among them, the wet skid resin is gradually put on the market as a functional resin with improvement wet skid resistance.

According to the EU REACH regulations, the production of tires mostly uses environmentally friendly oils that do not contain polycyclic aromatic hydrocarbons to replace aromatic oils. The reduction of aromatic oil, has a negative impact on the dynamic performance of tires. R & D personnel try to balance various properties of tread rubber by adjusting various raw materials, such as replacing oil with functional anti-slip resin in the formula. The addition of anti-slip resin plays a plasticizing role in rubber processing without affecting the rubber At the same time, it can improve the anti-slip properties of the rubber compound.

Excellent anti-slip resin has suitable softening point, suitable Tg, and has good compatibility with the rubber matrix. Used in tread rubber, it can significantly improve the anti-slip properties of tread rubber, To improve wear resistance, will not have a negative impact on rolling resistance and the remaining physical properties.

This work studies the effect of Fihonor anti-slip resin on the physical properties, dynamic mechanical properties and dynamic viscoelastic properties of high-performance tread rubber.

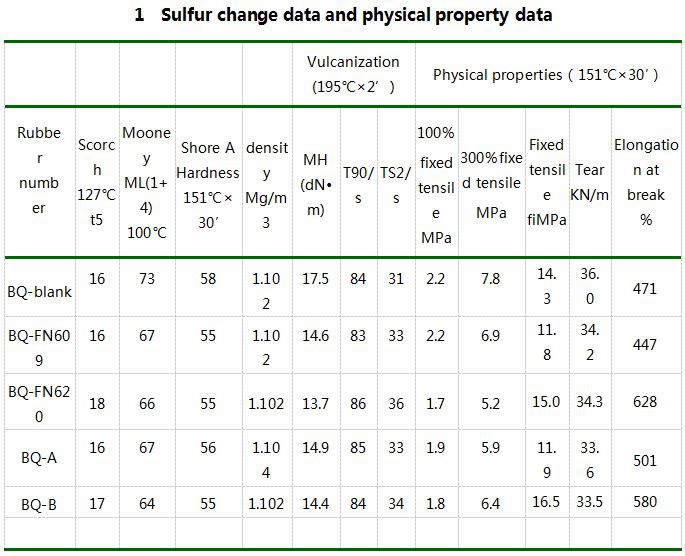

1.1 Physical properties

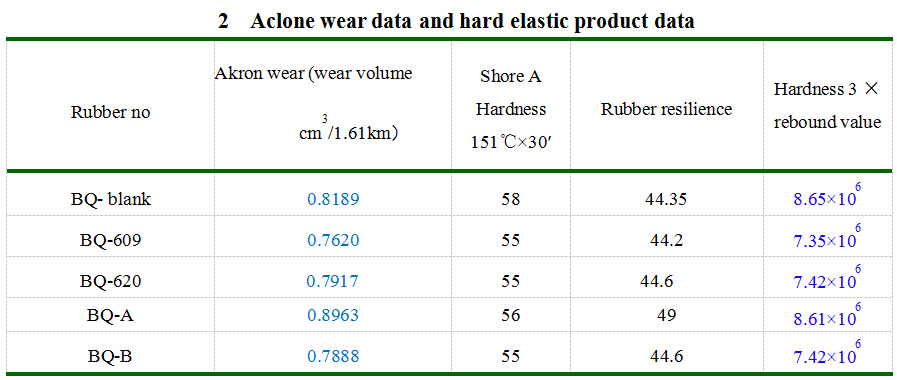

1.2 Wear resistance

Table 2 is the statistics of the product of the Aclone abrasion data, hardness value, rubber resilience data and the cubic value of the hardness and the rebound value of the various types of anti-slip resin compounds.

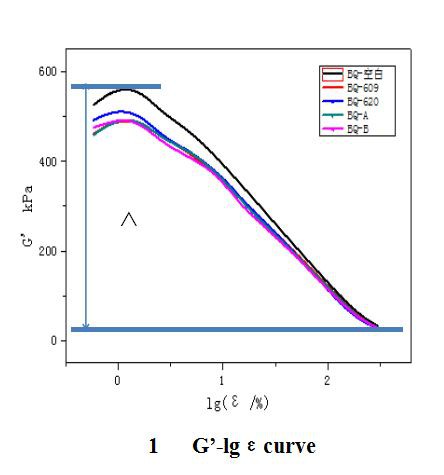

1.3.1 Influence of anti-wet slip resin on rubber compound processability and filler dispersibility

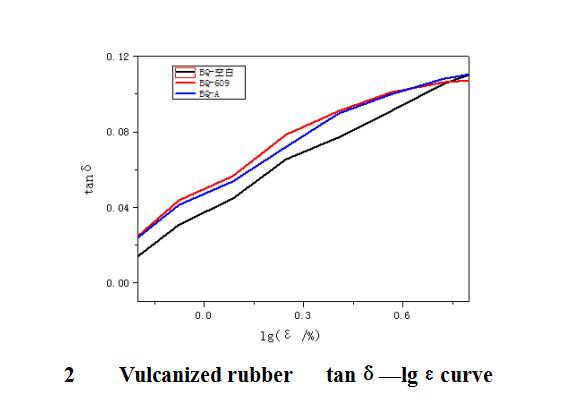

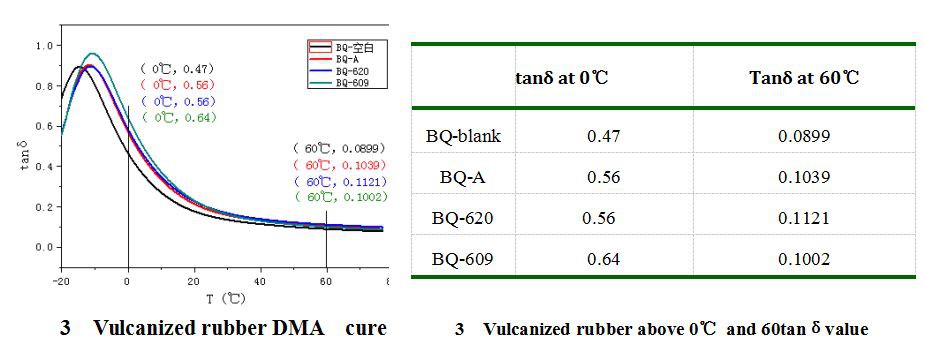

1.3.2 Influence of anti-wet slip resin on the dynamic properties of vulcanizates

1.4 Dynamic viscoelastic properties

(1) In terms of physical properties, the compound with Fihonor FN609 and FN620 has better processability and better wear resistance;

(2) In terms of wet skid resistance, it can be known from the properties of DMA and dynamic heat generation that the compound added with Fihonor FN609 and FN620 has good wet skid resistance and has little effect on rolling resistance;

(3) Fihonor Anti-wet slip resin has good compatibility with the matrix rubber, which is conducive to improving the processing performance of the compound rubber, and Fihonor can produce and recommend anti-wet slip with better compatibility for customers according to their needs Resin.