liupeng@fihonor.com

julie@fihonor.com

+86-13475839195

+86-13070805560

Apr 20, 2020

Rubber protective wax is mainly divided into ordinary paraffin wax and microcrystalline wax. Paraffin is a vacuum distillate. As raw materials, commercial paraffin can be obtained through solvent dewaxing and deoiling, refining, molding, and packaging.

Paraffin wax is divided into soap wax, crude wax, semi-refined wax, and fully refined wax, etc., having a variety of grades according to the melting point, regular grades are 54 # and 58 # paraffin.

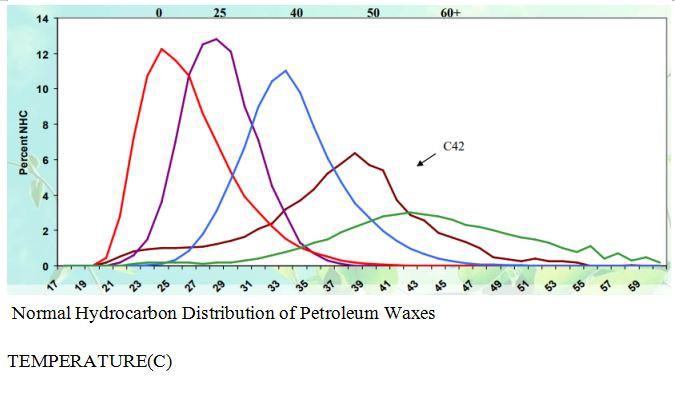

The relative molecular weight of paraffin wax is lower than microcrystalline wax, generally, between 300 and 500, the number of carbon atoms is mainly 20 to 35, the relative density is 0.86 to 0.94, the melting point is 30 to 70 ° C, and the paraffin from some large flake crystal. The major ingredient of commercial paraffin is normal paraffin, and it also contains isoparaffin, monocycloalkanes, bicyclic cycloalkanes, monocyclic aromatic hydrocarbons, and bicyclic aromatic hydrocarbons.

Microcrystalline wax is refined by vacuum residue oil as raw material, its crystal is small, relative molecular weight is 500 to 700, the carbon number is mainly 35 to 55, and the dropping point is 60 to 90 ℃. The molecular structure of Microcrystalline wax is more complex than paraffin, the mass fraction of normal kinds of paraffin and aromatic hydrocarbons are small.

The mass fractions of isoparaffins and long side-chain naphthenes are large. (The chemical nature of microcrystalline wax is relatively lively, Reacts violently with fuming sulfuric acid, producing foam and heat, while paraffin does not react, Is inactive. )

Alkanes with a low carbon number have a relatively low molecular weight, low melting point, low branching degree, and are easy to migrate from the rubber to the rubber surface, but when the temperature is increased, alkanes with a lower carbon number will dissolve in the rubber, so they are supersaturated slowly at high temperatures, caused the migration speed to slow down, and even the migration speed is zero.

Alkanes with a high carbon number have a large molecular weight, a high melting point, and a high degree of branching, so their migration resistance is large and their migration speed is slow. When the number of carbon atoms is higher, the migration speed is slower, the resulting wax film is too thin to form a protective layer, and has almost no protective effect on rubber.

Rubber protective wax is mainly composed of normal kinds of paraffin (straight-chain paraffin), isoparaffins (branched paraffin) and cyclic hydrocarbons (cyclic paraffin and aromatic hydrocarbons with long chains). When the relative molecular weight is the same, normal alkanes migrate faster than isoparaffins, and the more isoparaffin branches, the slower the migration speed. Cyclic hydrocarbons with long side chains migrate most slowly.

Normal alkanes crystallize into large flakes and are loose, and ozone in the atmosphere easily penetrates the wax film to attack the rubber surface. When a certain amount of isoparaffin is added to normal paraffin, the regularity of crystalline molecules is destroyed, so that a thin, amorphous and dense wax film can be obtained, thereby enhancing its ability to prevent ozone corrosion.

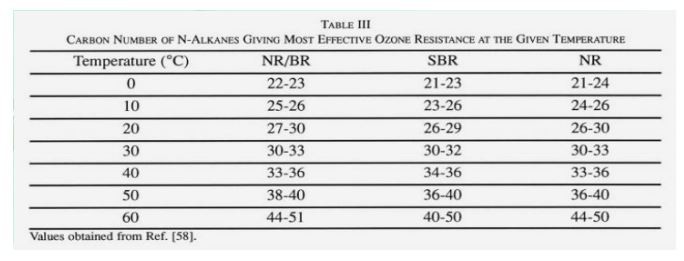

The use temperature of rubber is mainly in the range of -5 ~ 55 ℃. Ozone has an aging effect on the rubber. When the use temperature is lower than -5 ℃, due to the scarcity of activated molecules, There is not chemically react, that is, And the aging phenomenon does not occur; when above 55 ℃, ozone will decompose to generate harmless oxygen, so the rubber will not be aging due to ozone.

At low temperatures, the mobility of each component of the protective wax is reduced, and the sprayed wax film is an alkane with a low carbon number. This crystalline wax film is porous and loose. Due to the slow migration speed, the wax film formation speed is slow and thin, ozone starts to erode the surface of the rubber before the wax film is formed, so the protection under the low temperature is not easy.

At higher temperatures, the formation of a wax film is slow and thin because hydrocarbons with low carbon atoms dissolve in the rubber, making it difficult to form an appropriate protective film.

Different rubber compounds have different adaptability to the protective wax. For example, in the NR / SBR / BR system, the protective effect of microcrystalline wax is significantly better than ordinary paraffin. In the NR / CIIR system, tests in the laboratory ozone aging box show that the effect of microcrystalline wax and ordinary paraffin is similar. Depending on the compound, the results of exposure may sometimes be reversed. For example, the experimental results of the NR / CIIR system show that ordinary paraffin wax is superior to microcrystalline wax, while NR / SBR / BR system microcrystalline wax is significantly superior to ordinary paraffin wax.

After adding fillers, some fillers will promote the migration of protective wax. The filler's more active, the wax will migrate faster. Such as channel carbon black, white carbon black, lamp smoke carbon black, etc .; some fillers will inhibit and slow the migration of protective wax. If calcium carbonate filler is added, the ejection speed will be reduced below the completely filler-free compound.

Some softeners (such as aromatic hydrocarbon oils) will delay the migration and ejection of paraffin wax, while some softeners (such as n-alkanes) will accelerate the migration and ejection of paraffin wax. Migration/ejection is related to temperature. When the temperature is increased (such as 40 ℃), the protective wax is more soluble in n-paraffin oil, so the amount of frost is reduced; when the temperature is lower, the n-paraffin oil will enhance the migration of the protective wax.

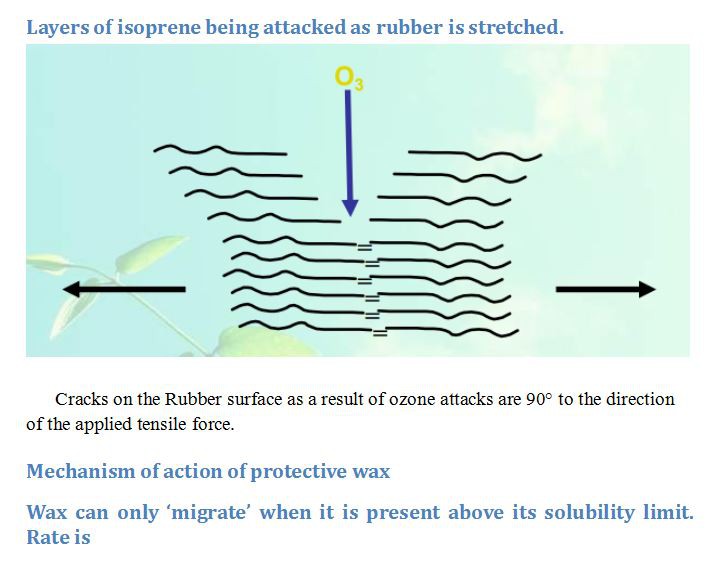

In order to provide protection against ozone attack, the wax must generate a surface film which is …

Continuous

Impervious

Homogenous

Flexible

Aesthetic