liupeng@fihonor.com

julie@fihonor.com

+86-13475839195

+86-13070805560

Jun 01, 2020

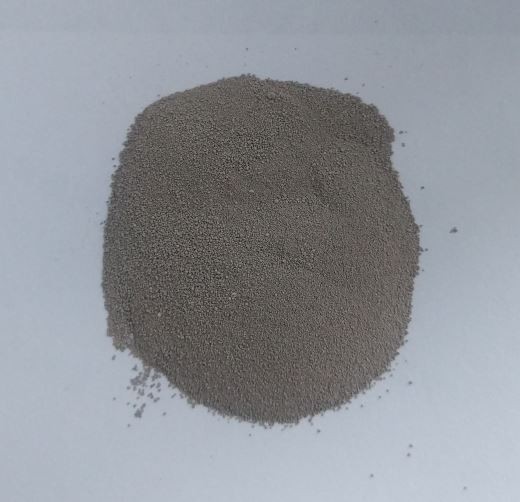

Ultrafine particle size, average particle size is 500nm (8000-10000 mesh)

| term | unit | Value |

| density | g/cm³ | 2.2-2.8 |

| dimension (-2um) | % | 92-98 |

| Sieve residue | (325mesh)Sieve residue% | ≤0.002 |

| Moisture | % | 0.5-1.0 |

| PH | 5-8 |

Compared with ordinary production formulas, the compound with a nano-level reinforcing material, strong powder, has similar Mooney viscosity and vulcanization characteristics, and physical properties have been improved, especially the tensile strength of the compounds has been significantly improved compared with normal production formulas. The aging resistance is better, and the performance of the finished product is also improved accordingly.

After strong carbon powder replaces carbon black, the rubber compound has better resilience and the corresponding material has lower heat generation.

● High filling and high reinforcement: The surface has been specially modified to have good reinforcement performance in various rubbers. Its reinforcement performance is equivalent to that of carbon black N550, N660, and can be used to reinforce rubber in synergy with carbon black and white carbon black. And less affect physical properties.

(Lower hardness and poorer wear resistance)

● Outstanding airtight performance: Due to its own sheet structure, it has excellent barrier performance (airtightness), so it is used in tire airtight layers, inner tubes, basketball bladders and other formulations to replace carbon black. Reduce the comprehensive mechanical properties of rubber compounds.

● Good physical and mechanical properties: used in various rubbers, it can significantly improve the processing stability, elasticity, flex resistance, flame retardancy and other physical and mechanical properties of the rubber compound, and can significantly improve the dynamic and static ratio of the rubber, can be applied to rubber shock absorbers