liupeng@fihonor.com

julie@fihonor.com

+86-13475839195

+86-13070805560

May 26, 2020

· It is an important measure of green manufacturing, energy saving and emission reduction in rubber industry.

· It can meet the demand of green tire adding a lot of silica.

· Improve the physical and mechanical properties of rubber compound, especially the tear resistance of engineering tire

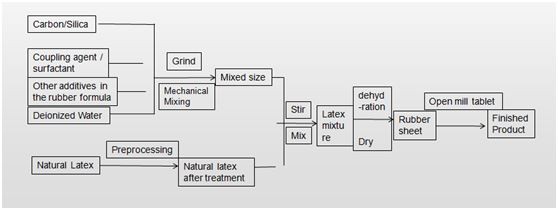

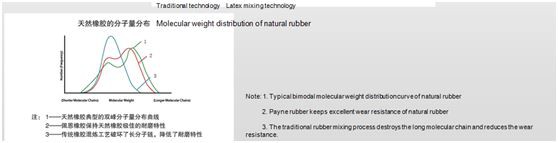

Fihonor latex mixing technology instead of traditional compound mixing method, not only eliminates the traditional process of mixing, such as process, more important can maximize reserve the bimodal distribution of the molecular structure of natural rubber, make all kinds of rubber performance greatly improved, with excellent flexibility, cutting resistance to tear and abrasion resistance. Low - cost, high - performance and environment - friendly production technology have been found in rubber processing field.

LTM technology: Latex mixing technology

Payne Modification: Surface modification of Nano particles

· High dispersion of carbon black particles in latex;

· The latex particles precipitate with carbon black to achieve the uniform distribution of carbon black.

· The adsorption capacity of surfactant on the surface of carbon black is as low as possible to increase the direct contact between carbon black and latex.

· High quality natural latex

· Inherent properties of strength, resilience and cut resistance

· Superior performance over time in both wet and dry applications

· Extensive range of sheet rubber, lining and fabricated products, moulded products and hose

· Lowest cost of ownership

The latex mixing technology makes the polymer structure of natural rubber be preserved to the maximum extent without damage. The innovative controllable modification technology of nano particles makes the mixing of additives in rubber faster, more uniform and more stable. The unique formula makes the service life of rubber longer. The technology comes from seven patents of the company.

Contact us

Wechat/WhatsApp:+8613518628501

Email: edward@fihonor.com