liupeng@fihonor.com

julie@fihonor.com

+86-13475839195

+86-13070805560

Jun 12, 2020

White-side wall rubber is air tightness a special production high, special rubber mixed viscosity, excellent curing properties. The white-side wall rubber is mainly used for high-end off-road car tires, SUV tires and some high-end vehicles tire decoration and the LOGO. Because of its excellent performance and beautiful appearance, white-side wall tire is becoming more and more popular.

Because of the particularity of white-side wall tire special requirements on the performance and appearance of the white-side wall tire and rubber formulation, manufacturing technology of white-side wall tire is more complicated, the process requirements more stringent, usually made of white-side wall tire is a side of a tire factory quality and technical strength to reflect. Fihonor chemical collection of Bridgestone, HANKOOK, Kumho, white-side wall and many other well-known international enterprises mix formula and technology expertise, with excellent R & D team innovation and upgrading, the development of a new type of white-side wall rubber formulation and process technology, to overcome the technical problems of domestic white-side wall compound. The products have been popularized and applied in many famous tire manufacturing factories in China.

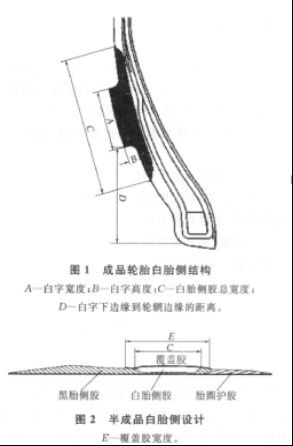

The finished tire white-side wall structure shown in Figure 1. Semi finished products of white-side wall film as shown in Figure 2

2.1. White-Side Wall Rubber Color Pollution:

Recommended measures:

1) Use and maintain attention to avoid contamination of foreign objects and impurities.

2) Every time before production required by white-side wall rubber washing machine, washing machine with rubber and rubber treatment alone, can not contact with water and separant.

2.2. The Influence Of Temperature And Speed On Extrusion:

Recommended measures:

1) when the extrusion temperature is low, the surface of the film is rough, and it is easy to produce spongy and wavy shape. It is suggested that the manufacturers adjust the equipment according to the conditions of the equipment (reference extrusion temperature 95-105 C, line speed: 9-11 m /min).

Contact us

Wechat/WhatsApp:+8613518628501

Email: edward@fihonor.com